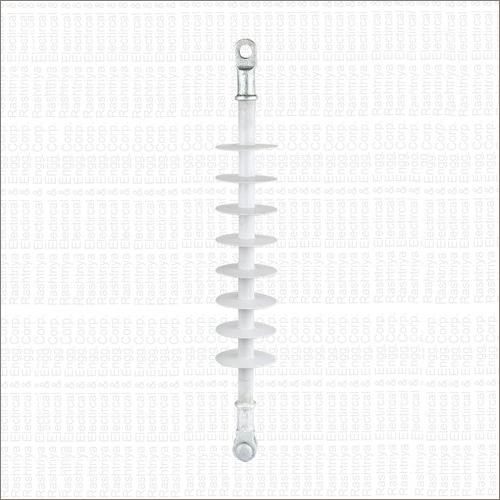

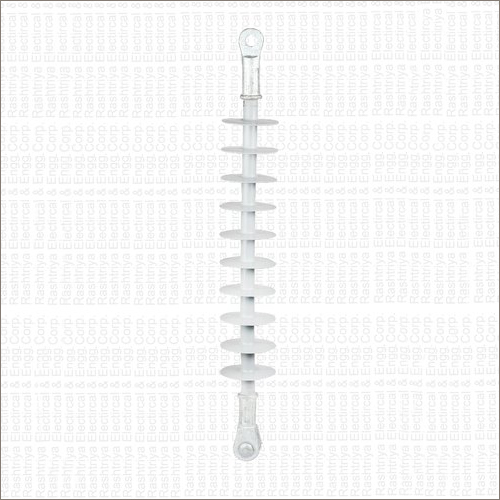

33Kv 90 Kn Type Disc Insulator

Price 325 INR/ Piece

33Kv 90 Kn Type Disc Insulator Specification

- Layer

- Single

- Feature

- Anti-fog, Weather & Corrosion Resistance

- Surface Treatment

- Glazed

- Size

- 255 x 130 mm

- Thermal Conductivity

- 0.2 W/mK

- Coating Type

- Silicone Rubber Coated

- Installation Guideline

- Suitable for suspension and tension string; follow standard mounting procedures for 33kV lines.

- Density

- 2.4 Gram per cubic centimeter(g/cm3)

- Product Type

- Disc Insulator

- Material

- Polymer

- Rated Voltage

- 33 kV

- Tensile Strength

- 90 kN

- Width

- 255 mm

- Thickness

- 130 mm

- Application

- Electrical Distribution Line

- Breakdown Voltage

- 75 kV (Dry) / 95 kV (Wet)

- Heat Conductivity

- Low

- Color

- Grey

- Max Withstanding Temperature

- -40C to +70C

- Power Frequency Flashover Voltage (Dry/Wet)

- 80/65 kV

- Creepage Distance

- 400 mm

- Impact Strength

- High (meets IEC 60383 requirements)

- Corrosion Resistance

- Excellent (suitable for industrial and coastal environments)

- Standard

- IEC 60383, IS 731

- Insulator Type

- Cap and Pin Type

- Cantilever Strength

- Min. 12 kN

- Weight

- 5.2 kg (approx.)

33Kv 90 Kn Type Disc Insulator Trade Information

- Minimum Order Quantity

- 500 Pieces

- Payment Terms

- Cash Advance (CA)

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About 33Kv 90 Kn Type Disc Insulator

Specification

| Working Voltage | 33 kV |

| Rated Voltage | 33 kV |

| Packaging Type | 12 Pieces per Corrugated Box |

| Minimum Creepage Distance | 900 mm |

| Material | Polymer insulator |

| End Fitting Type | T&C (Tongue & Clevis) Type. polymer insulator |

| Capacity | 33kV 90kN |

| Brand | Rashtriya electrical & engg corp |

| Color | Silver |

| Weight | 1.20 kgs |

| Visible Discharge Voltage | 33 kV |

| Tensile Strength | 90 kN |

| Usage/Application | Electrical Distribution Line |

| Voltage | 33 kV |

33Kv 90 Kn Type Disc Insulator is functional as the tension insulator as well as suspension insulator that can be used for distribution lines as well as high voltage transmission. It is known for fulfilling the needed electromechanical strength. It is known well for providing support and insulation to the line conductors in tension as well as suspension systems. 33Kv 90 Kn Type Disc Insulator offered by Rashtriya Electrical & Engineering Corporation, can withstand minimum mechanical strengths, and provides improved operation.

Superior Electrical Insulation

This disc insulator is designed to provide exceptional electrical insulation performance in 33kV distribution lines. Its optimized creepage distance of 400 mm and advanced polymer material help reduce leakage currents and withstand harsh weather, making it reliable in both dry and wet conditions as evidenced by its high flashover voltage ratings.

Robust Mechanical Strength for Demanding Conditions

With a minimum tensile strength of 90 kN and cantilever strength of 12 kN, the insulator offers excellent support for overhead lines. The high-impact resistance, compliant with IEC 60383 standards, ensures durability even under mechanical stress, vibrations, or impact in utility and industrial applications.

Weather and Corrosion Resistant Design

A specially glazed surface and silicone rubber coating safeguard the insulator against environmental impacts. Its anti-fog and corrosion-resistant properties make it suitable for installation in coastal, industrial, and areas with severe pollution, ensuring a long operational life and lower maintenance needs.

FAQs of 33Kv 90 Kn Type Disc Insulator:

Q: How is the 33kV 90 kN Type Disc Insulator installed on electrical distribution lines?

A: This insulator is suitable for both suspension and tension string configurations. Installation follows standard mounting procedures for 33kV lines, ensuring the cap and pin assembly is securely attached using specified hardware.Q: What benefits does the anti-fog feature provide to the insulator?

A: The anti-fog property minimizes the accumulation of moisture and contaminants on the insulators surface, reducing the risk of flashover and enhancing dielectric performance in foggy or humid climates.Q: When should this insulator be chosen over traditional porcelain types?

A: Select this polymer-based disc insulator when superior corrosion resistance, lower weight, and enhanced weather performance are needed, particularly in coastal or industrial environments where pollution and salt exposure are prevalent.Q: Where can the 33kV 90 kN Disc Insulator be installed?

A: It is ideal for medium voltage overhead distribution lines, especially in industries, urban power networks, and regions with challenging weather or pollution conditions, such as coastal or high-humidity areas.Q: What are the main advantages of the silicone rubber coating?

A: This coating delivers excellent hydrophobicity, chemical resistance, and insulation, ensuring reduced leakage currents, improved contamination performance, and long-term reliability even in harsh weather.Q: How does the product comply with international standards?

A: It is manufactured to meet IEC 60383 and IS 731 standards, ensuring recognized quality, performance, and safety requirements for disc insulators in electrical utilities.Q: What is the recommended temperature range for the insulators operation?

A: The insulator is designed to perform optimally in environments ranging from -40C to +70C, making it well-suited for extreme temperature variations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polymer Disc Insulator Category

33KV 45KN Disc Insulator

Price 250 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Grey

Product Type : Disc Insulator

Application : Electrical Distribution Line

Material : Polymer

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry